Shop by Category

Resources & Info

George E. Booth Co., LLC has a longstanding professional relationship with Endress+Hauser and has consistently been one of the largest representatives of Endress+Hauser instrumentation products for more than 20 years. Scroll through this page for various informative resources.

VIDEO RESOURCES

PROLINE

Focuses on innovative solutions which ensure high plant availability and seamless documentation in an internal logbook.

TANKVISION

Tankvision is a highly modern tank gauging system with unique properties which make your inventory data easily available.

FUNCTIONAL SAFETY

This animation shows a short introduction on Safety Integrity Levels in general.

LIQUIPHANT SAFETY

Level limit detection for liquids in safety demanding applications.

LEVELFLEX FMP55

Safe and precise interface measurement even in the case of emulsion, due to SensorFusion - the combination of the capacitance and guided radar measuring principle.

MICROPILOT

Reliable and universal level measurement.

MEASUREMENT PRINCIPLES

CORIOLIS

Born in 1792, the French mathematician and physicist Gustave Gaspard de Coriolis was the first to describe the force that history has named after him. This force is particularly noticeable in rotating systems.

ULTRASONIC

Illustration of the ultrasonic flow measuring principle.

VORTEX

Illustration of the vortex flow measuring principle.

ELECTROMAGNETIC

Illustration of the electromagnetic flow measuring principle.

THERMAL

Illustration of the thermal flow measuring principle.

DIFFERENTIAL PRES.

Illustration of the differential pressure flow measuring principle using the pitot tube.

MEASUREMENT SOLUTIONS

Discover how Endress+Hauser answers to challenges faced in a sludge digester when measuring biogas flow.

READ MORE

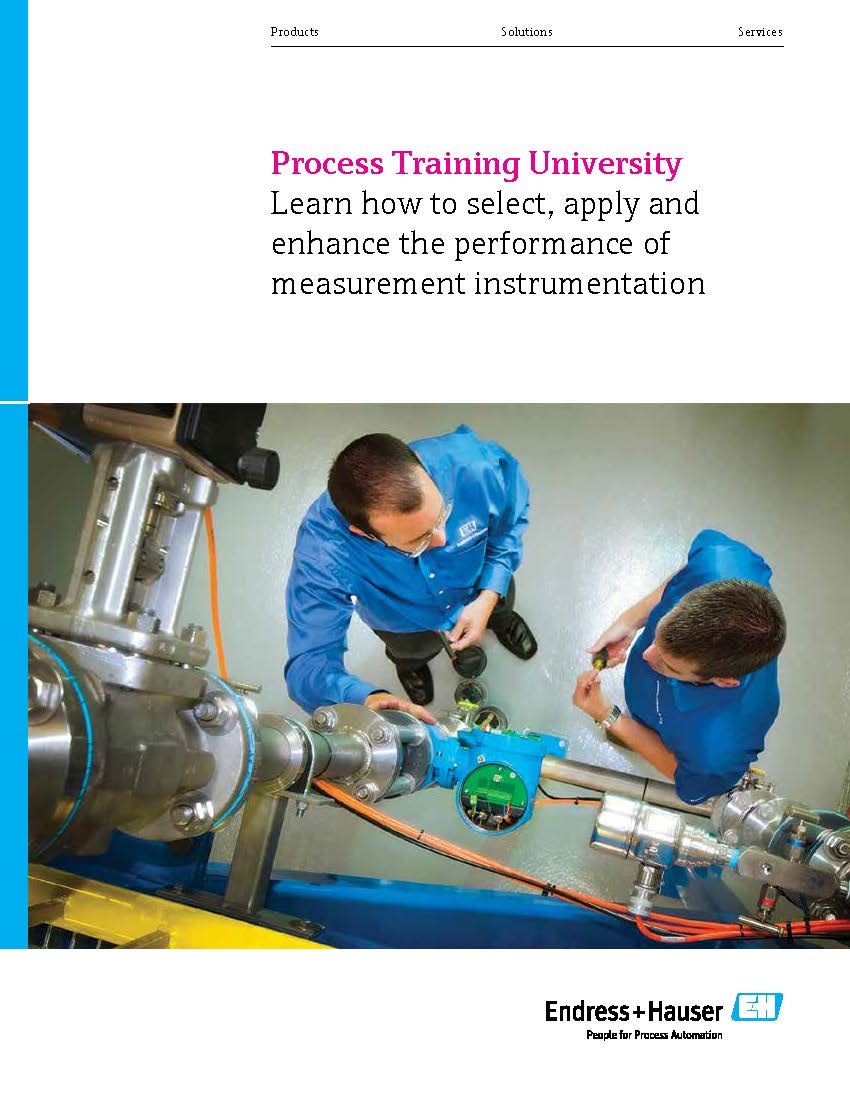

PTU FACILITIES PROVIDE A UNIQUE HANDS-ON TRAINING EXPERIENCE

The PTU® (Process Training Unit) is an integrated process automation system, giving customers unique, hands-on training. Our instrumentation training will significantly help your maintenance and engineering staff learn the latest technology for dealing with maintenance issues that may arise, whether they are newly-hired or have years of experience. There are PTUs at several locations across the U.S., with Midwestern locations in Romeoville, IL and Greenwood, IN.